1. INTRODUCTION

The global competitiveness, seeking increased

profitability, has become the main objective of the companies in the current

environment due to the expansion of segments in the same production chain. This

aspect brings the constant need for improvement of organizational production

system, boosting the use of administrative strategies which assist in the

selection of appropriate techniques and tools to achieve a better industrial

production, ensuring their stay in the market (BORGES; OLIVEIRA; OLIVEIRA,

2013). Every production process, no matter how good are their management, and

their activities achieve controlled and planned tasks, it is still possible to

identify points to be improved (GOETSCH; DAVIS, 2014).

In this sense, among many existing theories, the

approach called World Class Manufacturing (WCM) shows to be efficient with

regard to elimination of losses and has been able to enter into organizations

that aim to achieve high levels of perfection in their production levels. In

concomitant period the WCM approach was to rise the Lean philosophy, known in

organizational environments such as Lean Production System and had to cradle

the Toyota Production System, which has been studied and applied as a

management model to inherit a strong culture that is characterized by the production

control through perfect techniques, continuous improvement, and that has

brought excellent results to organizations over the years (SMITH, 2011).

The reflection of great importance in the business

world can be seen through the quantitative analysis of publications related to

topics discussed here. Performing a matter of Lean Production in the Brazilian

metasearch portal CAPES Periodicals (Higher Education Personnel Improvement

Coordination) are identified 2.623 articles published in peer-reviewed journals

over the past five years (2010-2015). Since the search for the subject WCM

resulted in a total of 6.070 documents. However, although the large number of

studies between these two topics in the literature, there are not available

research that shows this interrelationship of WCM approach and the Lean

Production System techniques, featuring this regard a research gap.

This way, before these two themes, the Systematic

Literature Review (SLR) becomes all-important, as it can provide other

researchers find study materials have been finalized and filtered. It also

allows time and resources economy, provides mapping in which specific areas the

studies are being developed and it is possible and most relevant checking for

gaps in the literature that can be explored by other researchers have not yet

identified the lack of studies review (CONFORTO; AMARAL; SILVA, 2012). These

factors, this research seeks to answer the problem checked: In what areas of

study are concentrated scientific research involving topics Lean Production and

World Class Manufacturing? In this context, this research has aimed at making a

Systematic Literature Review (SLR) to identify how to configure the

publications that relate WCM and Lean Production.

For development of the present study it was divided

into sections, where the first part deals with the introduction, objectives,

found problems, and the importance that justifies this production. The second

section consists of literature review, which enabled the explanation and origin

of the themes elucidated. The third topic contains the explanation of the

adopted methodological concepts, from carrying out the procedures used to

collect data as well as construction of the database. The fourth part shows the

results. By the end, the fifth and final section reports the considerations of

all developed production.

2. THEORETICAL FOUNDATION: WCM AND LEAN PRODUCTION

The origin of

the concept of WCM took place in the 1980s through case studies of successful

companies (BORGES; OLIVEIRA; OLIVEIRA, 2013). His term was coined by Hayes and

Wheelwright (HAYES; WHEELWRIGHT, 1984) to describe the capabilities developed

by Japanese and German companies, which had a higher level of production when

compared to other industries. The excellent performance in global competition

of these companies generated the term "World Class Manufacturing"

(EID, 2009).

The WCM includes

success against competitors and organizational profitability in a competitive

international environment. His approach is related to the absolute competitive

advantage and the best producers (HOSSEINIE; SHIRAZI; ASHLOGHI; MEHR, 2012;

PALUCHA, 2012) can define this as the best practice. Based on 10

interconnections, called pillars, which relate the manufacturing process and

maintain and enable an organization to achieve world class (GAJDZIK, 2013;

PALUCHA, 2012; ZIMWARA; GORIWONDO; MHLANGA; CHASARA; CHUMA, 2012). These

pillars are divided in: safety, cost deployment, focused improvement,

autonomous activities, professional maintenance, logistics, early management,

people development and environment, and quality control (GAJDZIK, 2013;

PALUCHA, 2012; ZIMWARA; GORIWONDO; MHLANGA; CHASARA; CHUMA, 2012).

Achieve the

performance of a world-class organization involves important assignments,

including: become a globally successful manufacturer; recognize the business

environment and free competition, threats, opportunities and competitive

advantages; and prepare and stay in this environment with industrial planning

and manufacturing (HOSSEINIE; SHIRAZI; ASHLOGHI; MEHR; AN, 2012).

The competitive

advantages pointed to an organization that achieves world-class are studied and

listed in different ways by different authors that characterize points as

improved profitability, training, product development, better quality, quick

reaction against competitors, production programs, attention to customer needs,

reasonable prices, delivery, flexibility, quality management, reducing the

supply of goods, cost of production, innovation, strategy, systems and

structures, accountability, performance measurement, values and fundamental

objectives, culture and competitors (BORGES; OLIVEIRA; OLIVEIRA, 2013;

CHIARINI; VAGNONI, VAGNONI, 2014; SCHONBERGER, 1996).

These different

features that allow pointing to competitive advantage and classify the

organization as a world class result in the attempt by the researchers to

establish models to measure and classify an organization such as WCM

(HOSSEINIE; SHIRAZI; ASHLOGHI; MEHR; AN, 2012; PALUCHA, 2012; NG; HUNG, 2001;

ASKARI, 2004; MOTWANI; KUMAR; KATHAWALE; KATHAWALE; WCM, 1994). Other researches

also aimed to identify the critical success factors for the implementation of

WCM (XIE, 1995; SVENSSON; KLEFSJO, 2001).

Note, through

these studies conducted in various research fronts, there is still need for

further elucidate a topic considered again, and it lacks progress in its

theory. It is known (PALUCHA, 2012) that the adoption of a management

organization, in accordance with the principles of WCM, is based on reliable methods,

high quality tools, and extensive involvement of all employees and company

managers. Also in the management aspect, Yamashina (2000) cited by (BORGES;

OLIVEIRA; OLIVEIRA, 2013) complements the use of WCM is divided into four

steps: identify the problem, identify the loss, define the method to be adopted

for restoration and control the results.

The elucidated

points that depict the WCM as the organizational pursuit of excellence through

modern approaches, the use of techniques and tools and the elimination /

minimization of losses in the process, brings a strong adherence to the

principles of the philosophy of Lean Production System (PALUCHA, 2012).

The main

appearance of the Lean Production system happened at the end of World War II,

when the Japanese industry had to rethink their production model, appearing

then the Toyota Production System (TPS), which due to the lack of productive

resources, sought to produce lowest possible cost, especially fighting waste

(OHNO, 1988).

The term Lean

Production was set in the late 1980s in a research project at the Massachusetts

Institute of Technology (MIT), who studied the global automotive industry, with

the main focus on the Japanese model of Toyota, aiming to map best practices

industry, through interviews with employees, union and government officials.

The Lean Production System's philosophy identifying and minimizing or phasing

out of waste sources, based on five fundamental principles: the definition of

(i) value from the view of the customer and their needs, and then determined

the necessary activities to offer the product to the customer at the lowest

level waste through the definition of (ii) the value chain. Search is then

manufacturing the product using a (iii) continuous flow; which is triggered

only when the client makes the request. That is, using a (iv) Pull Production.

From these four principles and the use of continuous improvement (kaizen) or radical improvements (kaikaku) is reached the fifth (v)

fundamental principle that is the perfection of the system (CALARGE; PEREIRA;

SATOLO; DIAZ, 2012). These waste minimization or elimination (Muda in Japanese) are crucial for companies

to optimize their activities and to eliminate times and processes that do not

add value and are classified into seven types, namely: overproduction, waiting,

transportation, motion, over processing, rework and inventory (VINODH;

DEVADASAN; VIMAL; KUMAR, 2013).

When reviewing

the implementation of Lean Production system in enterprises, it is noted that

it can use various techniques and tools, which should take place in a

coordinated and structured way (PETTERSEN, 2009; HUNTER, 2004) and assist in

this process of minimization and / or elimination of waste, bringing results

for the organization as reducing lead times, reduced costs, improved quality

and increased productivity, making them agile and more competitive (WALTER;

TUBINO, 2004; SAURIN; RIBEIRO; MARODING, 2010). Thus, the techniques and tools

are a great help in improving a product or process in various kinds of

organizations (FELD, 2001).

Within this

context, there is a strong synergy between the World Class Manufacturing

approach (WCM) to achieve competitiveness with global levels recommended by the

great performance and reduce waste, and that can be implemented through the use

of Lean philosophy, and the techniques and tools that support this system.

3. RESEARCH METHOD

This research can be considered theoretical because it

was developed with bibliographical sources of information gathered through the

metasearch portal of CAPES journals along the bases of the Production

Engineering and Human and Social Sciences. In these bases were found 24 search

sources, among which are cited as an example: Academic Search Premier - ASP

(EBSCO), Cambridge Journals Online, Emerald Insight (Emerald), OECD iLibrary,

Oxford Journals (Oxford University Press), SAGE Journals online, SciELO.org,

ScienceDirect (Elsevier), SpringerLink, Wiley online Library, and others. These

data were needed for the construction of bibliometric indicators of scientific

production. However, this study is also an applied research, possessing

quantitative and qualitative aspects (NEUMAN, 2009).

This research may also, as your goal, be classified as

methodologically descriptive because in the search for information and

characteristics of the particular subject seeking to know the factors involved,

the objectives outlined, and the targeting of studies (MONSEN; HORN, 2007).

The technique employed to conduct the analysis of

publications in this study is bibliometric. This type of survey is one of the

methods developed for the systematic review of the literature on a subject or

more proposed, having been worked by the Belgian Paul Otlet, which generated

over a new field for the measurement of all aspects relating to the

publication, reading books and documents, and thus has a characteristic of

being methodical, transparent and replicable (ROUSSEAU, 2014; COOK; MULROW;

HAYNES, 1997).

A literature review allows to assess with complete

accuracy and reliability surveys conducted among specific topics, mapping where

papers are published and allowing the researcher generates existing knowledge

summaries of the results (CONFORTO; AMARAL; SILVA, 2012).

This research adopted the methodology created by Levy

and Ellis (LEVY; ELLIS, 2006), (see Figure 1) which shows a SLR through a

process consists of three steps that meet the criteria of this study. However,

some modifications and adjustments were needed to comply with the standards

defined herein to be achieved, which also reinforce and create the foundation

for responding to problems and thus remain the goal.

Figure 1. The three steps to conduct a Systematic Literature

Review

Source:

Levy and Ellis (2006)

The process as described, is divided into three

stages, where the second stage is the highest concentration of business (LEVY;

ELLIS, 2006):

Step 1: Input - its main point is to define the issue

proposed connecting all the facts and the objective of which must be very well

aligned so that there is clarity and are feasible (CRESWELL, 2013). Above all,

here are initiated primary searches on pre-identified databases and stations as

collection points, among so you need full attention and rigor in the

collection, since this data will become a search of the database (CONFORTO;

AMARAL; SILVA, 2012). For this study we performed a time frame in the

corresponding period of the last five years (2010 to 2015), where this way it

was possible to raise a current database, with demonstration of the latest

articles published.

Step 2: Processing - Concentrate the six data

processing stages, which are the most important, being comprised as follows:

1st. Stage - To know the literature: identify

publications and separate them based on goals;

2nd. Stage - Comprehend the literature: the detailing

of information is essential to obtain and interpret what the authors of the

research aimed and performed in their studies;

3rd. Stage - Apply: make revisions to search for

possible errors in understanding and extracting the necessary parts to compose

the survey. As a modification to this research was adopted string searches to

refine again the publications of the base taken the first step. In that sense

it is necessary to test the combinations adopting the words to the specificity

sought thereby to can highlight the importance of carrying out a database for

each survey (CONFORTO; AMARAL; SILVA 2012).

4th. Stage - Analyze: is understood in carrying out an

analysis of the results to identify what factors include the research

objectives through filters, which can perhaps incompatible delete reference to

the purpose of the study, which began in the third stage;

5th. Stage - Synthesize: consists of assembling or

creating clearly ways to expose the results. Among the ways: charts, tables,

images can be built in helping to improve the outlook. From now on, this

research was used for the assembly of the social networking Ucinet® software

that interconnects with the NetDraw®, and the word cloud by Wordle®;

6th. Stage – Evaluate: describe the results achieved

through the analysis and compilation of data, and by the end, to answer the

problems found and make considerations about the whole study developed.

Step 3: Output - It is connected with the output of

the whole process conducted where it can be disposed in the assessment base

built for the research, which in the process of remaking Step 2 as many times

as necessary can be excluded by checking and finding that really. It does not

belong to adopted people (LEVY; ELLIS, 2006).

A set of the desired information search strategies

constituted by words or phrases applied with Boolean operators - which consist

of informing the metasearch how to combine the necessary terms. Although the

use of signs that can be closed is an expression, and separate the terms in

cells (SCHNEIDER; EVANS, 2012). It used the Boolean operators AND and OR, as

well as quotes in the truncation of words by objectified search. The AND function

is to narrow the search by combining the terms making the intersection of joint

research. Already the OR operator is the grouping of terms, expanding research,

since many words have leads. The quotation marks have the function to search

for exact grouping of words (BARKER; BARKER, 2013).

This way, for raising this study, the search strings

were rethought so that the derivatives of words were also found being applied

in isolation and later the crossing of the following: (i) "lean

production" OR "lean manufacturing"; (ii) "world class

manufacturing" OR "world-class" OR "word-class

manufacturing"; (iii) "lean production" OR "lean

manufacturing" AND "world class manufacturing" OR "world-class"

OR "word-class manufacturing".

In this light, better elucidated in Figure 2, were

found at the intersection of terms 98 publications where to apply the second

stage adopted the methodological model has resulted in the delineation of 42

(AL-BAIK; MILLER,2014; ZULKIFFLI, 2010).

Figure 2: Results of search strings.

4. RESULTS

As noted in section 3, 42 articles that address the research themes were

identified. Table 1 lists these articles. The column "Article Number"

stands out as the basis for locating the articles in the figures related to the

analysis of social networks. The authors, year of publication and the published

periodical are presented along with this numbering.

Table

1: List of selected articles considered in current study

|

Article

Number |

Authors |

Year |

Periodical |

|

1 |

GURUMURTHY; KODALI |

2011 |

Journal of Manufacturing Technology

Management |

|

2 |

DEMETER; MATYUSZ |

2011 |

International Journal of Production

Economics |

|

3 |

HEDELING; JACKSON |

2011 |

Journal of Manufacturing Technology

Management |

|

4 |

TOHIDI |

2012 |

Advances in environmental biology |

|

5 |

FORRESTER; SHIMIZU; SORIANO-MEIER; GARZA-REYES; BASSO |

2010 |

Journal of Manufacturing Technology

Management |

|

6 |

MEYBODI |

2013 |

Advances in Competitiveness Research |

|

7 |

PONG; MITCHELL |

2012 |

The British Accounting Review |

|

8 |

TANCO; SANTOS; RODRIGUEZ; REICH |

2013 |

International Journal of Advanced Manufacturing

Technology |

|

9 |

ANGELIS; CONTI; COOPER; GILL |

2011 |

Journal of Manufacturing Technology

Management |

|

10 |

VINODH; ARVIND; SOMANAATHAN |

2010 |

Journal of Manufacturing Systems |

|

11 |

CHOWDARY; GEORGE |

2011 |

Journal of Manufacturing Technology

Management |

|

12 |

BOZICKOVIC; MARIC |

2013 |

DAAAM international scientific book |

|

13 |

RAHMAN; LAOSIRIHONGTHONG; SOHAL |

2010 |

Journal of Manufacturing Technology

Management |

|

14 |

ALONY; CAPUTI; COLTMAN |

2011 |

Issues in informing science &

information technology |

|

15 |

WANG; MING; KONG; LI; WANG |

2011 |

Forest Products Journal |

|

16 |

ESAN; KHAN ; QI; NAYLOR |

2013 |

Journal of Manufacturing Technology

Management |

|

17 |

MONGE; CRUZ; LOPEZ |

2013 |

Informacion Tecnologica |

|

18 |

FURLAN; DAL PONT; VINELLI |

2011 |

International Journal of Production

Economics |

|

19 |

PAIVA |

2010 |

International Journal of Production

Economics |

|

20 |

WIENGARTEN; PAGELL |

2012 |

International Journal of Production

Economics |

|

21 |

NAOR; LINDERMAN; SCHROEDER |

2010 |

Journal of Operations Management |

|

22 |

KISPERSKA-MORON; DE HAAN |

2011 |

International Journal of Production

Economics |

|

23 |

BRANDT; THUN |

2010 |

World Development |

|

24 |

TYAGI; CHOUDHARY; CAI; YANG |

2015 |

International Journal of Production

Economics |

|

25 |

BORTOLOTTI; BOSCARI; DANESE |

2015 |

International Journal of Production

Economics |

|

26 |

VINODH; DEVADASAN; VIMAL; KUMAR |

2013 |

Journal of Manufacturing Technology

Management |

|

27 |

SHAN; WANG; XIN; BI |

2013 |

International Journal of Production

Economics |

|

28 |

BORADE; BANSOD |

2010 |

Journal of Manufacturing Technology

Management |

|

29 |

THAKKAR; KANDA; DESHMUKH |

2012 |

Journal of Manufacturing Technology

Management |

|

30 |

VIEIRA JUNIOR; LUCATO; VANALLE |

2014 |

Journal of Manufacturing Technology

Management |

|

31 |

O’SULLIVAN; ANDREONI; LÓPEZ-GÓMEZ; GREGORY |

2010 |

Oxford Review Of Economic Policy |

|

32 |

GARBIE |

2011 |

Journal of Service Science and

Management |

|

33 |

PENG; VERGHESE; SHAH; SCHROEDER |

2013 |

Journal of Supply Chain Management |

|

34 |

BACCHETTI, ANDREA; SACCANI, NICOLA |

2012 |

Omega |

|

35 |

SHAHIN; ATTARPOUR |

2011 |

Modern Applied Science |

|

36 |

AL-BAIK; MILLER |

2014 |

Empirical Software Engineering |

|

37 |

ZULKIFFLI |

2010 |

International Journal of Business and

Management Science |

|

38 |

MEYBODI |

2010 |

Advances in Competitiveness Research |

|

39 |

KRISTENSEN; ISRAELSEN |

2014 |

Management Accounting Research |

|

40 |

CHOWDHURY |

2014 |

Business Horizons |

|

41 |

GONZALEZ; MARTINS |

2014 |

Journal of Knowledge Management |

|

42 |

CLOSS; SPEIER; MEACHAM |

2011 |

Journal of the Academy of Marketing

Science |

A starting point to highlight is the variety of authors with

publications throughout the period investigated. It can be observed that of the

42 publications in only four occur the repetition of authors, as in the case of

Meybody (2010; 2013) and Vinodh et al. (2010) and Vinodh et al. (2013). This

aspect demonstrates that the subject is still in a phase of exploration, and

there are no researchers in the current period of research and among the bases

researched, which stand out in terms of number of publications.

This fact does not occur when verifying the journals adopted by the

researchers when presenting the society their researches. The 42 publications

identified are published in 25 journals, of which two (Journal of Manufacturing

Technology Management and International Journal of Production Economics) stand

out by concentrating 45.2% of the publications.

In Figure 3 the quantitative representation of publications over the years

was developed. Of these papers, 24% are published in 2011, showing that this

way there was a drop in production over this period by the year 2015, as seen

in Figure 3. This can be caused by a variety of reasons, from the researchers'

lack of interest in relating the issues to working on administrative strategies

in isolation.

It is also difficult to identify theoretical studies

that indicate how theoretical convergence occurs between the two administrative

strategies, and that in some articles that report practice in the business

environment highlight the positive results achieved, but do not outline the way

to tread for success.

Figure 3: Number of publications in the year’s survey.

Another analysis performed with regard to

methodological questions of the research, which are divided into four aspects:

(i)

objective of the research that can be understood in

three ways: (a) descriptive, when the process consists in the investigation,

interpretation of historical facts to get understanding; (b) exploratory, when

it is necessary to create a specific function to get results and; (c)

explicative, in which it talks about these facts for a justification from a

different point of view or to be the opposite, or even the need for a different

point on the subject.

(ii)

The second aspect is related to how the research (ii)

approach: characterized as (a) qualitative, when there is a focus on

interpreting rather quantifying, orientation for the process and not for the

result, preoccupation with context, in the sense that people's behavior and the

situation bind closely in the formation of experience and; (b) quantitative,

using structured procedures, formal data collection instruments under control

conditions.

(iii)

The third refers to the (iii) types of research, It

was identified the predominance of three: (a) case study, of empirical

investigating a particular phenomenon, usually contemporary, within a real life

context, when the boundaries between the phenomenon and the context in which it

inserts are not clearly defined; (b) survey, comprising a data collection on a

significant sample about a problem to be studied for, then by quantitative

analysis, obtain them conclusions corresponding to the data collected and; (c)

conceptual, which is connected to the study of existing theories and

explanations of the concepts and techniques used.

(iv)

Ultimately, the latter deals with the (iv) analysis

tools and data collections that understand: (a) documentary, which is employed

by the survey documents that characterize the data and employment relationships

with research and; (b) form, which aims at collecting and analyzing data

through statistical procedures, it is their preconceived investigations by

relationships of ideas (YIN, 2010; MIGUEL, 2011; CASSELL; SYMON, 1994; MARCONI;

LAKATOS, 2002).

The Figure 4 summarizes this analysis and indicates

that research using mostly of an exploratory methodology with a qualitative

approach, it is developed by case studies and application forms.

Figure 4: Percentage of employees questions about the purpose, approach, techniques, and methods for data collection.

This aspect can be explained by the term Lean

Production concept is inherited from the Toyota Production System, which was

born in the automotive sector (YAMASHINA, 2000). Large companies with high

power and production technology that use such methods becoming search target

for the development of studies and developments of theory. However, as is the

quantitative approach is related to several different attempts at achieving

measure processes in respect to construction of algorithms, or software.

This shows that the scientific productions inherent in

the issues under study are in traditional sectors of transformation of

industrial goods, and few studies conducted by the agro-industrial sector and

services.

Figure 5: Percentage of concentration of research

sectors.

The publications on the searched subjects have been

conducted by researchers from different countries, highlighted in Figure 6. We

identified 24 countries published in the period surveyed, involving 145

researchers. The United States are the largest producer of research on the

issues and have the majority of researchers, being 41 in total. The UK and

India stand out with 22 and 15 researchers, respectively, followed by Brazil,

Canada and China with 8 researchers each. These six main generators of

knowledge countries concentrate 70% of the publications.

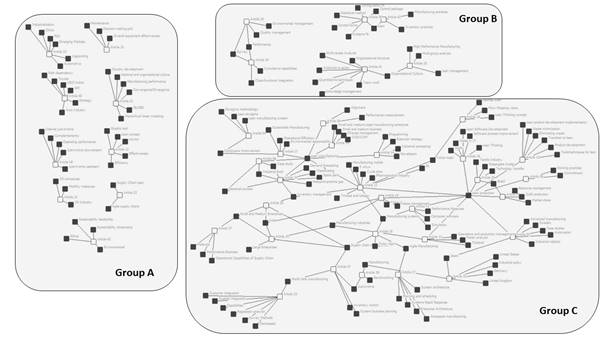

Figure 6: Number of researchers by countries.The Figure 7 projects the social network of identified articles and their correlation with the keywords. This construction allows display as a set of actors that have correlation with each other, in which can be of different types present different contents as well as different structural properties (WORRELL; WASKO; JOHNSTON, 2013).

Figure 7: Number of network publications in the years survey. In analyzing social networks, the most important aspect is to identify the most cohesive subgroups of actors (SCOTT, 2012). It is noted that this network of actors presents three main groups.· Group A - Made up of 9 articles (BOZICKOVIC; MARIC,2013; BRANDT; THUN, 2010; CHOWDHURY,2014; CLOSS; SPEIER; MEACHAM; MEACHAM, 2011; FURLAN; DAL PONT; VINELLI, 2011; KISPERSKA-MORON; HAAN, 2011; NAOR; LINDERMAN; SCHROEDER, 2010; GARBIE, 2011; SHAHIN; ATTARPOUR, 2011), which are isolated and address issues isolated from other works identified.

· Group B - has 6 articles divided into two small groups of common themes, formed by Articles (DEMETER; MATYUSZ, 2011; KRISTENSEN; ISRAELSEN, 2014; PAIVA, 2010; WIENGARTEN; PAGELL, 2012; BORTOLOTTI; BOSCARI; DANESE, 2015; GONZALEZ; MARTINS, 2014).

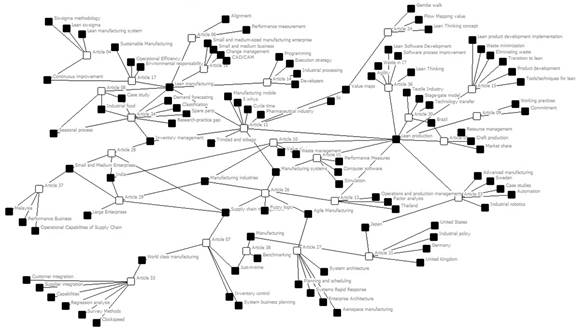

· Group C - Group of greater concentration of research topics, formed by the 27 remaining articles, and that the main focus of relations issues. This network is displayed most prominently in Figure 8.

Figure 8: Group C network actors. The Figure 8 details a network feature to be in training, and in some decentralized points where we have a low connection with other themes, as in articles on the outskirts of the figure. However, at times it presents itself as a distributed network, such as the articles located in the central part of the figure with strong links between keywords and articles (SCOTT, 2012). This shows that the research WCM and Lean Production is still at an early stage to mature, where the themes are initiating greater interaction, demonstrating that researchers can already go on the association themes.

This stage of low maturity refers to the classification of Grandori and Soda (1995) for a Social Asymmetric Network, in other words, a configuration not governed by formal contracts in relationships, and asymmetry between the surveyed subjects (higher prevalence of certain themes, though not occur extreme asymmetries). This classification is quite consistent, and predictable, since the opposing themes have not yet established their areas of concentration and performance, or in the terminology of Flingstein (1996) their organizational fields.

The World Class Manufacturing keyword, which was one of the search terms, presented in a single connection and is used for only two publications as keywords. Already the word Lean Production is more binding and strength. A possible understanding of this context can be understood because metasearch Portal CAPES use search across the full text when allocated a word or term, being considered all the elements such as title, abstract, keywords, and all remainder. Still referring to social network analysis, is strengthened by the word cloud job in Figure 9, the power to simulate the amount of repetition that keywords present when allocated in order to achieve tabular. This cloud shows that there is a concentration of words Lean Production, small and medium enterprises, inventory management, lean manufacturing, supply chain management, manufacturing systems, and India. Note that the term World Class Manufacturing presents little attention within the research, confirming that while research on the subject are conducted, there is a low citation index compared theme Lean Production. Figure 9: Word cloud of the keywords you incorporate in publications (2010-2015)

5. CONCLUSIONS

This study is proposing to conduct a bibliometric

research publication on the topics Lean Production and World Class

Manufacturing. The metasearch Portal CAPES that joins various high reference

scientific bases and reliability was used. They identified 42 publications that

addressed the issues in the last five years and this goal has identified

important aspects about the studies conducted.

As for the identified results, we note that during the

years 2010 and 2011 more researches were developed and that by the year 2014

these studies were in decline. Even until the first half of 2015 were found

within the metasearch only two publications. It is assumed, which is slow the

studies of investigation time, and also that each journal has dates for

publication of their volumes, thus changing the result to the current year's

end.

It was found that although distributed to

publications, research has their researchers as a country of origin the United

States showing greater contribution to the development of themes. However,

denoted Japan, the country where it was inherited one of the subjects, with

only one participant researcher will be shown.

Regarding the study of the network of actors, note

that this is presented in an early stage to maturity, appearing for the most

part as decentralized, but with actions to become distributed in some subjects,

indicating that researchers. They begin to glimpse the association between

topics.

REFERENCES

AL-BAIK,

O.; MILLER, J. (2014) Waste identification and elimination in information

technology organizations, Empirical Software Engineering, v. 19, n. 6,

p. 2019-2061.

ALONY,

I.; CAPUTI, P.; COLTMAN, T. (2011) Informing Implementers of Lean Strategy in

Process Industries-The Central Role of Schedulers, Issues in Informing

Science & Information Technology, v. 8, p. 335.

ANGELIS

J.; CONTI, R.; COOPER, C.; GILL, C. (2011) Building a high-commitment lean

culture, Journal of Manufacturing Technology Management, v. 22, n. 5, p.

569-586.

ASKARI,

A. (2004) An integrated strategic model to achieve world class manufacturing

(ISM-WCM) (Doctoral Dissertation), University of Science & Technology,

Tehran, Iran.

BACCHETTI,

A.; SACCANI, N. (2012) Spare parts classification and demand forecasting for

stock control: Investigating the gap between research and practice, Omega,

v. 40, n. 6, p. 722-737.

BARKER,

D. I.; BARKER, M. (2013) Internet research illustrated, 7th,

Stanford, Cengage Learning.

BORADE,

A. B.; BANSOD, S. V. (2010), Study of vendor-managed inventory practices in

Indian industries. Journal of Manufacturing Technology Management, v. 21,

n. 8, p. 1013-1038.

BORGES,

R. C.; OLIVEIRA, E. H.; OLIVEIRA, A. S.; (2013) Study the implementation of the

pillar quality control of world class manufacturing methodology (WCM) in a

automotive company in the south of Minas Gerais (in portuguese), in: Proceedings

of the Simpósio de Administração da Produção, Logística e Operações

Internacionais, São Paulo: FGV, Brazil, p. 1-17.

BORTOLOTTI,

T.; BOSCARI, S.; DANESE, P. (2015) Successful lean implementation:

Organizational culture and soft lean practices, International Journal of

Production Economics, v. 160, p. 182-201.

BOZICKOVIC,

R.; MARIC, B. (2013) Lean concept--a challenge to managers for the better

future of the company, DAAAM International Scientific Book, v. 1, n. 1,

p. 491-510.

BRANDT,

L.; THUN, E. (2010) Thun, The fight for the middle: upgrading, competition, and

industrial development in China. World Development, v. 38, n. 11, p.

1555-1574.

BUCHANAN

D.; HUCZYNSKI, A. (2004) Organizational behavior, 5 ed., Harlow,

Prentice-Hall.

BURCHER,

P.; STEVENS, K. (1996) Measuring up to World Class Manufacturing, Aston

Business School.

CALARGE,

F. A.; PEREIRA, F. H.; SATOLO, E. G.; DIAZ, E. C. (2012) Evaluation of Lean

Production System by using SAE J4000 standard: case study in Brazilian and

Spanish automotive component manufacturing organizations, African Journal of

Business Management, v. 6, n. 49, p. 11839-50.

CASSELL,

C.; SYMON, G. (1994) Qualitative methods in organizational research,

London, Sage Publications.

CHIARINI,

A.; VAGNONI, E. (2014) World-class manufacturing by Fiat. Comparison with

Toyota Production System from a strategic management, management accounting,

operations management and performance measurement dimension, International

Journal of Production Research, v. 53 n. 2, p. 590-606.

CHOWDARY,

B. V.; GEORGE, D. (2011) Improvement of manufacturing operations at a

pharmaceutical company: a lean manufacturing approach. Journal of

Manufacturing Technology Management, v. 23, n. 1, p. 56-75.

CHOWDHURY,

S. D. (2014) Strategic roads that diverge or converge: GM and Toyota in the

battle for the top, Business Horizons, v. 57, n. 1, p. 127-136.

CLOSS,

D. J.; SPEIER C.; MEACHAM, N. M. (2011) Sustainability to support end-to-end

value chains: the role of supply chain management. Journal of the Academy of

Marketing Science, v. 39, n. 1, p. 101-116.

CONFORTO,

E. C.; AMARAL D. C.; SILVA S. L. (2012) Roadmap for systematic literature

review: application in product development and project management (in

portuguese), in: Proceedings of the Congresso Brasileiro de Gestão de

Desenvolvimento de Produto–CBGDP, Porto Alegre, Brazil, p. 1-12.

COOPER, H. (1998) Synthesizing Research, Thousand Oaks,

Sage.

COOK,

D. J; MULROW, C. D.; HAYNES, R. B. (1997) Systematic reviews: synthesis of best

evidence for clinical decisions. Annals of Internal Medicine, v. 126, n.

5, p. 376-380.

CRESWELL,

J. W. (2013) Research design: qualitative, quantitative, and mixed methods

approaches, Thousand Oaks, Sage Publications.

DEMETER,

K.; MATYUSZ, Z. (2011) The impact of lean practices on inventory turnover. International

Journal of Production Economics, v. 133, n. 1, p. 154-163.

EID,

R. (2009), Factors affecting the success of world class manufacturing

implementation in less developed countries. Journal of Manufacturing

Technology Management, v. 20, n. 7, p. 989–1008.

EDOSOMWAN,

J. A. (1996) Strategies for World-Class Manufacturing: the quality observer. Management

Science and Engineering, v. 6, n. 3, p. 6-9.

ESAN,

A. O.; KHAN, M. K.; QI, H. S.; NAYLOR, C. (2013) Integrated manufacturing

strategy for deployment of CADCAM methodology in a SMME, Journal of

Manufacturing Technology Management, v. 24, n. 2, p. 257-273.

ESCRIG-TENA,

A. (2004) TQM as a competitive factor: a theoretical and empirical analysis, International

Journal of Quality & Reliability Management, v. 21, n. 6, p. 612-37.

FARISH,

M. S. (1995) Strategies for World Class Products. England. Gower:

Hampshire.

FELD,

W. M. (2001) Lean manufacturing: tools, techniques, and how to use them.

New York, CRC Press.

FLIGSTEIN,

N. (1996) Markets as politics: a political-cultural approach to market

institutions, American Sociological Review, v. 61, n. 4, p. 656-673.

FORRESTER,

P. L.; SHIMIZU, U. K.; SORIANO-MEIER, H.; GARZA-REYES, J. A.; BASSO, L. F. C.

(2010) Lean production, market share and value creation in the agricultural

machinery sector in Brazil, Journal of Manufacturing Technology Management,

v. 21, n. 7, p. 853-871.

FURLAN,

A.; DAL PONT, G.; VINELLI, A. (2011) On the complementarity between internal

and external just-in-time bundles to build and sustain high performance

manufacturing. International Journal of Production Economics, v. 133, n.

2, p. 489-495.

GAJDZIK,

B. (2013) World class manufacturing in metallurgical enterprise, Metalurgija,

Croatia, v. 52, n. 1, p. 131-134.

GARBIE,

I. H. (2011) Implementation of agility concepts into oil industry. Journal

of Service Science and Management, v. 4, n. 2, p. 203.

GILGEOUS,

V.; GILGEOUS, M. A. (1999) Framework for manufacturing excellence, Integrated

Manufacturing Systems, v. 10, p. 33-44.

GOETSCH,

D. L.; DAVIS, S. B. (2014) Quality management for organizational excellence,

New Jersey, Pearson.

GONZALEZ,

R. V. D.; MARTINS, M. F. (2014) Mapping the organizational factors that support

knowledge management in the Brazilian automotive industry. Journal of

Knowledge Management, v. 18, n. 1, p. 152-176.

GRANDORI, A.; SODA, G. (1995) Inter firm

networks: antecedents, mechanism and forms, Organization Studies, v. 16, n. 2, p. 183-214.

GUNASEKARAM,

A. (2000) World Class Manufacturing in small and medium enterprises, International

Journal of Manufacturing Technology and Management, v. 7, p. 777-789.

GURUMURTHY,

A.; KODALI, R. (2011) Design of lean manufacturing systems using value stream

mapping with simulation: a case study, Journal of Manufacturing Technology

Management, v. 22, n. 4, p. 444-473.

HAYES,

R. H.; WHEELWRIGHT S. C. (1984) Restoring our competitive edge: competing

through manufacturing, Wiley, New York.

HEDELIND,

M.; JACKSON, M. (2011) How to improve the use of industrial robots in lean

manufacturing systems, Journal of Manufacturing Technology Management,

v. 22, n. 7, p. 891-905

HOSSEINIE,

S. M. S.; SHIRAZI, A. N. M.; ASHLOGHI, A. T.; MEHRAN, M. H. (2012) The combination of soft system and

quality function deployment methodologies in the design and development of the

comprehensive model world class manufacturing processes. Management Science

and Engineering, Canada, v. 6, n. 2, p. 22-34.

HUNTER,

S. L. (2004) Ten Steps to Lean Production. FDM Management, v. 76, n. 5, p. 20-23.

KISPERSKA-MORON

D.; HAAN, J. (2011) Improving supply chain performance to satisfy final

customers: “leagile” experiences of a polish distributor, International

Journal of Production Economics, v. 133, n. 1, p. 127-134.

KRISTENSEN,

T. B.; ISRAELSEN, P. (2014) Performance effects of multiple control forms in

a Lean organization: A quantitative case study in a systems fit approach,

Management Accounting Research, v. 25, n. 1, p. 45-62.

LEVY,

Y.; ELLIS, T. J. (2006) A system approach to conduct an effective literature

review in support of information systems research, Informing Science Journal,

v. 9, p. 181-212.

MCADAM,

R.; HENDERSON, J. (2004), Influencing the future of TQM: internal and external

driving factors. International Journal of Quality & Reliability

Management, v. 21, n. 1, p. 51-57.

MARCONI, M. A.;

LAKATOS, E. M. (2002) Técnicas de pesquisa: planejamento e execução de

pesquisas, amostragens e técnicas de pesquisas, elaboração, análise e

interpretação de dados. 4th, São Paulo, Atlas.

MEYBODI

M. Z. (2013) Alignment of Strategic Benchmarking Performance Measures: A Lean

Manufacturing Perspective, Journal of Competitiveness Studies, v. 21, n.

1/2, p. 14.

MEYBODI,

M. Z. (2010) The impact of just-in-time practices on consistency of

benchmarking performance measures, Advances in Competitiveness Research,

v. 18, n. 1/2, p. 73.

MONGE C.; CRUZ J.; LÓPEZ F. (2013) Impacto de la

manufactura esbelta, manufactura sustentable y mejora continua en la eficiencia

operacional y responsabilidad ambiental en México, Información tecnológica,

v. 24, n. 4, p. 15-32.

MONSEN,

E. R.; HORN, L. V. (2007) Research: successful approaches, American

Dietetic Association.

MOTWANI,

J.; KUMAR, A.; KATHAWALE, Y.; WCM, Y. (1994) Practices of North American

Manufacturing Organizations. Journal of Industrial Management & Data

Systems, v. 94 n. 7, p. 18-23.

MIGUEL,

P. A. C. (2011) Research methodology in engineering production and

operations management, 2th São Paulo, Elsevier.

NAOR,

M.; LINDERMAN, K.; SCHROEDER, R. (2010) The globalization of operations in

Eastern and Western countries: Unpacking the relationship between national and

organizational culture and its impact on manufacturing performance, Journal

of Operations Management, v. 28, n. 3, p. 194-205.

NEUMAN,

W. L. (2009) Social research methods: qualitative and quantitative

approaches, 7th, New Jersey, Pearson.

NG,

K. C.; HUNG, I. W. (2001) A model for global manufacturing excellence, Work

Study, v. 50, p. 63-68.

OAKLAND,

J. S. (2001) Total Organizational Excellence: achieving World Class

Performance, Oxford, Elsevier.

OHNO,

T. (1988) Toyota Production System: beyond large scale production,

Cambridge, Productivity PR.

O’SULLIVAN,

E.; ANDREONI A.; LÓPES-GÓMEZ, C.; GREGORY, M. (2013) What is new in the new

industrial policy? A manufacturing systems perspective, Oxford Review of

Economic Policy, v. 29 n. 2, p. 432-462.

PAIVA,

E. L. (2010) Manufacturing and marketing integration from a cumulative capabilities

perspective, International journal of production economics, v. 126, n.

2, p. 379-386.

PALUCHA,

K. (2012) World class manufacturing model in production management. Science

and Engineering, Poland, v. 58, n. 2, p. 227-234.

PENG,

D. X.; VERGHESE, A.; SHAH. R.; SCHROEDER, R. G. (2013) The relationships

between external integration and plant improvement and innovation capabilities:

The moderation effect of product clock speed, Journal of Supply Chain

Management, v. 49, n. 3, p. 3-24.

PETTERSEN,

J. (2009) Defining lean production: some conceptual and practical issues, The

TQM Journal, v. 21, n. 2, p. 127-142.

PONG,

C. K. M.; MITCHELL, F. (2012) Inventory investment & control: How have UK

companies been doing?, The British Accounting Review, v. 44, n. 3, p.

173-188.

RAHMAN,

S.; LAOSIRIHONGTHONG, T.; SOHAL, A. S. (2010) Impact of lean strategy on

operational performance: a study of Thai manufacturing companies. Journal of

manufacturing technology management, v. 21, n. 7, p. 839-852.

ROUSSEAU

R. (2014), Library science: forgotten founder of bibliometrics. Nature,

v. 510, n. 218, p. 12.

SHAHIN,

A.; ATTARPOUR, M. R. (2011) Developing decision making grid for maintenance

policy making based on estimated range of overall equipment effectiveness, Modern

applied science, v. 5, p. 86.

SHAN,

S.; WANGA, L.; XINA, T.; BIB, Z. (2013) Developing a rapid response production

system for aircraft manufacturing, International Journal of Production

Economics, v. 146, n. 1, p. 37-47.

SHARMA,

M.; KODALI, R. (2008) Development of a framework for manufacturing excellence, Measuring

Business Excellence, v. 12, n. 4, p. 55-60.

SAURIN, T. A.; RIBEIRO, J. L. D.; MARODIN, G. A.

Marodin (2010) Identificação de oportunidades de pesquisa a partir de um

levantamento da implantação da produção enxuta em empresas do Brasil e do

exterior (in portuguese), Gestão & Produção, v. 17, n. 4, p. 829-841.

SCHNEIDER,

G. P.; EVANS, J. (2012) New perspectives on the internet: introductory,

9th, Stanford, Cengage Learning.

SCHONBERGER,

R. J. (1996) World Class Manufacturing: the next decade: building power,

strength, and value. New York, Free Press.

SCOTT,

J. (2012) Social network analysis, Thousand Oaks, Sage Publications.

SINCLAIR,

D.; ZAIRI, M. (2001) An empirical study of key elements of total quality based

measurement systems: a case study approach in the service industry sector. Total

Quality Management, v. 12, n. 4, p. 535-50.

SMITH,

A. D. (2011) Component

part quality assurance concerns and standards: comparison of world-class

manufacturers. Benchmarking: an international journal, v. 18, n. 1, p.

128-148.

SOHAL,

A. S.; Terziovski, M. (2000) TQM in Australian manufacturing: factors critical

to success, International Journal of Quality & Reliability Management,

v. 17, n. 2, p. 158-68.

SOUZA

S. S.; LIMA, C. R. C. (2003) Maintenance focused on reliability as a strategic

tool (in portuguese), in: Proceeding of the Encontro Nacional de Engenharia

de Produção, Ouro Preto, Brazil, p. 1-8.

SVENSSON,

M.; Klefsjo, B. (2001) Experiences from creating a quality culture for

continuous improvements in Swedish School sector by using self-assessments, Total

Quality Management, v. 11, n. 4-6, p. 800-807.

TANCO,

M.; SANTOS, J.; RODRIGUEZ, J. L.; REICH, J. (2013) Applying lean techniques to

nougat fabrication: a seasonal case study, The International Journal of

Advanced Manufacturing Technology, v. 68, n. 5-8, p. 1639-1654.

THAKKAR

J.; KANDA, A.; DESHMUKH, S. G. (2012) Supply chain issues in Indian

manufacturing SMEs: insights from six case studies, Journal of Manufacturing

Technology Management, v. 23, n. 5, p. 634-664.

TOHIDI,

H.; KHEDRILIRAVIASL, K. (2012) Six sigma methodology and its relationship with

lean manufacturing system, Advances in Environmental Biology, v. 6, p.

895-906.

TYAGI,

S.; CHOUDHARY, A.; CAI, X.; YANG, K. (2015) Value stream mapping to reduce the

lead-time of a product development process, International Journal of

Production Economics, v. 160, p. 202-212.

VIEIRA

JUNIOR, M.; LUCATO, W. C.; VANALLE, R. M. (2014) Effective management of

international technology transfer projects: Insights from the Brazilian textile

industry, Journal of Manufacturing Technology Management, v. 25, n. 1,

p. 69-99.

VINODH,

S.; ARVIND, K. R.; SOMANAATHAN, M. (2010), Application of value stream mapping

in an Indian camshaft manufacturing organization, Journal of Manufacturing

Technology Management, v. 21, n. 7, p. 888-900.

VINODH,

S.; SOMANAATHAN, M.; ARVIND, K. R. (2013) Development of value stream map for

achieving leanness in a manufacturing organization, Journal of Engineering,

Design and Technology, v. 11, n. 2, p. 129 - 141.

VINODH,

S.; DEVADASAN, S. R.; VIMAL, K. E. K.; KUMAR, D. (2013) Design of agile

supply chain assessment model and its case study in an Indian automotive

components manufacturing organization, Journal of Manufacturing Systems, v.

32, n. 4, p. 620-631.

WALTER,

O. M. F. C.; TUBINO, D. F. (2004) Methods of evaluation of the implementation

of lean manufacturing: a literature review and classification (in portuguese), Gestão

& Produção, v. 20, n. 1, p. 23-45.

WANG,

C.; MING, X. G.; KONG, F. B.; LI, D.; WANG, P. P. (2011) Focus on

implementation: a framework for lean product development, Forest Products

Journal, v. 61, n. 5, p. 411-421.

WIENGARTEN,

F.; PAGELL, M. (2012) The importance of quality management for the success of

environmental management initiatives, International Journal of Production

Economics, v. 140, n. 1, p. 407-415.

WORRELL,

J.; WASKO, M.; JOHNSTON, A. (2013) Social network analysis in accounting

information systems research, International Journal of Accounting

Information Systems, v. 14, n. 2, p. 127–137.

XIE,

W. (1995) How to implement world class operational management in effective

way in the initial stage: a case study

of Billerudkorsnäs, Degree project, in project management and operational

development, Second level, Stockholm, Sweden.

YAMASHINA,

H. (2000) Challenge to world-class manufacturing, International Journal of

Quality & Reliability Management, v. 17, n. 2, p. 132–143.

YIN,

R. K. (2010) Case Study: design and methods, 4th, Porto Alegre,

Bookman, 2010.

ZIMWARA,

D.; GORIWONDO, W. M.; MHLANGA S.; CHASARA, T.; CHUMA T. (2012) World Class

Manufacturing status assessment for a margarine producing company in Zimbabwe,

International Journal of Innovative Technology and Exploring Engineering,

v. 2, n. 1, p. 52-57.

ZULKIFFLI,

S. N. A. (2010) The impact of supply chain operational capabilities on business

performance of small and medium enterprises in Malaysia: a preliminary

analysis, International Journal of Business and Management, v. 3, n. 2,

p. 1.